We’ve been perfecting the process of manufacturing replacement concrete mixing drums since 1953.

Quality steel and experienced craftsmanship are the ingredients that make Shumaker truck drums the best in the business.

STANDARD DRUM SPECIFICATIONS

Shumaker Industries manufactures all new drums for all types of concrete mixer trucks including both front and rear discharge mixers of any make. Our truck drums are built by experienced craftsmen using quality steel from domestic mills, making Shumaker drums the best in the business.

Listed below are the standard specifications of every drum we make, the drum thickness options for both rear discharge and front discharge mixers, and other options from which you can choose. We can also build a custom drum just the way you want it.

STANDARD SPECIFICATIONS:

100% of plate steel milled in the USA.

100% of plate steel milled in the USA.- True thickness steel (3/16” = .187, 1/4” = .250).

- Shell and fins from AR 200 manganese steel.

- All new ¼” one-piece pressed dished head.

- One-piece pressed blades with weep holes for quality mixing and easier cleanup.

- Solid machined roller track.

- Automated submerged arc welding of outside seams which reduces blow-through while maintaining excellent weld finish.

- One bolt-on square manhole (front discharge two manholes). Round, quick-open manhole optional

- Shot blasted and electrostatically primed using a gray universal primer.

- Installation or delivery of the drum.

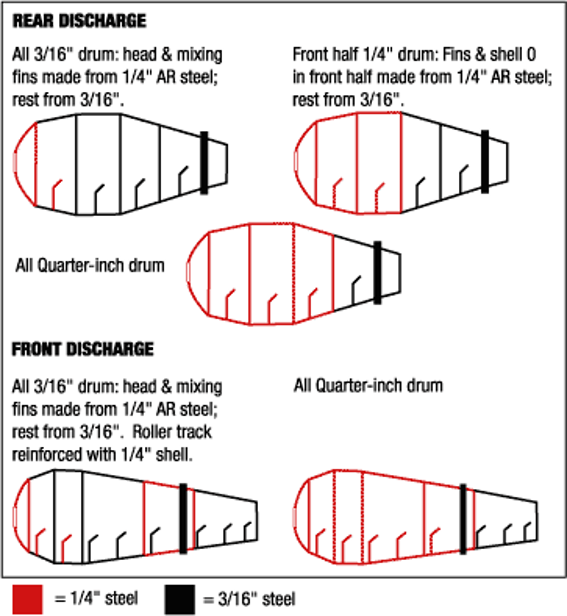

ALL 3/16” STEEL THICKNESS OPTION

The shell and blades of the drum are fabricated from our specialty 3/16” AR steel. You still get the all-new 1/4” dished head and the mixing blades will also be fabricated from our 1/4” AR steel.

FRONT HALF 1/4” OPTION

This option is unique to Shumaker replacement drums. With this option, you get 1/4” AR steel for the blades and shell in the front two (2) sections of the drum. The rest of the drum is of 3/16” AR steel. The front half 1/4” steel option gives you thicker steel in the high wear areas of the drum giving you the durability and long-life of an all 1/4” drum while saving money and overall weight. Available on rear discharge mixers.

ALL 1/4” OPTION

The shell and blades of the drum are fabricated from our specialty 1/4” AR steel.

Other Features

Rebar, divider blades (anti-surge blades), manholes (quick-open or bolt-on), front water injection, lifting hooks and paint are features we can add to your drum.

STEEL

Our goal at Shumaker Industries is to manufacture all new replacement truck drums that will last a long time. The single most important factor in making long-lasting replacement concrete mixer drums is using high-quality steel. The steel that goes into every Shumaker drum is a quality, high-strength, abrasion-resistant material. Read on to find out how we do it.

1. DEVELOP AN ONGOING RELATIONSHIP WITH A DOMESTIC SUPPLIER.

Shumaker Industries consistently purchases steel from domestic mills. During a time when prices have soared to over twice their recent value and fierce competition has forced other manufacturers to buy foreign material, Shumaker Industries has remained loyal to domestic mills because of their commitment to using the best steel in their drums and other products. Shumaker Industries does not purchase foreign market steel at a lower price because this material may have different physical properties from order to order. Instead, we control the quality of our plate material by purchasing from the same domestic mill in heat lots so that we receive quality plates that are consistent drum after drum, year after year.

2. DEVELOP A SPECIAL FORMULA FOR PLATE STEEL THAT MEETS THE DEMANDING WEAR REQUIREMENTS OF THE CONCRETE INDUSTRY.

Together with Shumaker Industries’ understanding of concrete mixers and domestic mills’ experience in producing high-quality specialty products, we have developed a formula that best serves the needs of the ready-mix concrete industry. In fact, the formula is proprietary in nature, meaning Shumaker Industries has sole rights to its use and no other manufacturer in the industry is permitted to use it.

3. THE RESULT IS A FORMULA FOR ABRASION RESISTANT (AR) PLATE THAT ACHIEVES THE FOLLOWING:

Average Brinell hardness of 200

Thru-plate hardness.

Brinell hardness refers to the surface hardness of the material. While this is significant, it is more important to achieve thru-plate hardness which allows the drum shell and blades to resist wear throughout the thickness of the plate, not just on the surface.

True thickness (3/16″ = .187” and 1/4″ = .250″)

Domestic plate and sheet metal are measured using the English system, while foreign mills use the metric system (millimeters). The result is that foreign market metals can often be several thousandths of an inch thinner than domestic metals. This can mean a built-in savings of around $800 over the life of the drum when domestic steel is used.

WORKMANSHIP

Shumaker Industries invests more money to use high grade domestic steel in our concrete mixer drums compared to the cost of a less expensive foreign market steel. Yet we are able to offset that cost by employing an efficient, experienced workforce.

EXPERIENCE

Our team of specialists has an average 15 years of experience with the company and are truly experts in the art of replacement drum fabrication.

COMMITMENT

Their commitment to the company, the ready-mix industry and quality workmanship result in a superior product for the ready-mix concrete producer.

FAMILY

With four active father & son teams, two additional teams with the father recently retired, and one team of three generations, our workforce is able to maintain a family atmosphere with a very efficient transfer of knowledge.

SHUMAKER INDUSTRIES EQUATION FOR QUALITY:

Experienced workforce (avg. 15 yrs. experience; 4 father/son teams)

+ Latest computer-controlled manufacturing equipment

+ New facility, two facilities set up specifically for replacement drum manufacturing

= HIGHEST VALUE PRODUCTS AT THE MOST COMPETITIVE PRICES.

Download Rear Discharge Order Sheet Here

-

Request a Quote