OUR FORMULA FOR BUILDING LONG-LASTING CENTRAL MIX DRUMS

Quality Materials — We use thick, high-quality American-milled steel plate for our central mix blades. We encourage you to compare our material thickness and properties with our competition. We believe in the tried and proven concept that Heavier steel = less flexing = less cracking = longer-lasting drum.

Desire to Be the Best — Built by guys who truly want to exceed your expectations. As a small to mid-sized company, we understand the connection between customer satisfaction and our job security.

Experience — When you consider the average length of employment is over 16 years for our production personnel, it is easy to feel assured that you are dealing with skilled workers that are definitely masters of their trade.

DRUM LINERS

Durex Liners In A New Drum

New Higher Weld Plate – Stronger Hold

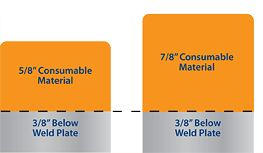

Thicker Liner Options Available

New Weld Plate – More Holes = More Power While we offer several great options for central mix blade liners, the actual drum liners themselves are almost always going to be urethane. No other material matches the wear properties at a comparable cost. So, if you need urethane drum liners why chose Durex? Because it lasts longer than any other urethane in the market. Check out this brochure (PDF) for more details.

- Single Pour – No peeling or delamination

- Molecularly Superior – Longer chains prevent micro tares

- Stronger Weld Plates – More urethane under plate flange prevents premature release

- More Weld Plates – More holding power

- 1.25” Thickness Available – Provides 40% more consumable material

- Professional Installation – Buy liners and installation in one call

Having spent more than 60 years in the industry, Shumaker Industries has seen and installed every major liner option available today. We believe Durex is currently the best option for long wear life and that is why we choose to install these liners in new drums and on existing drums in the field.

Call us for pricing on liners and installation for: Rex, Erie, Coneco, Johnson, Ross, Vince Hagen, Inventure, BMH etc.

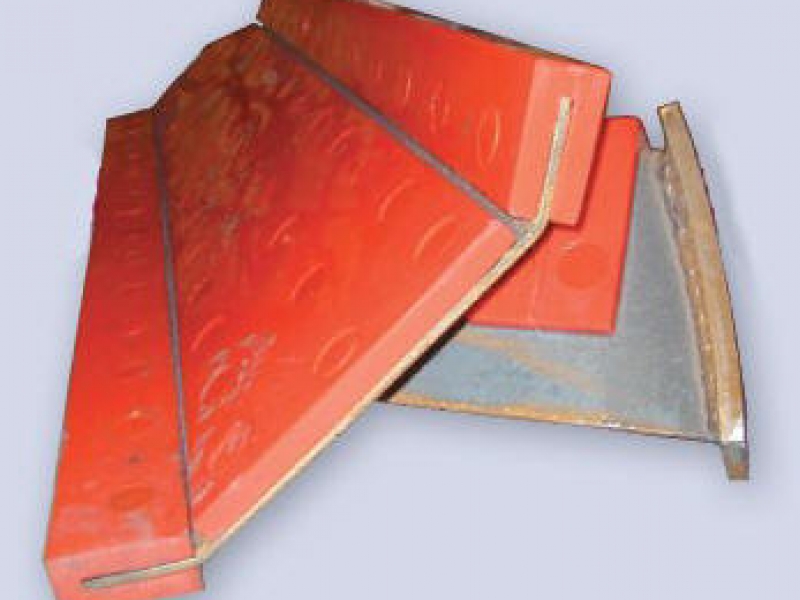

CENTRAL MIX BLADES – ALL MAKES WITH LINER OPTIONS

We manufacture replacement central mix blades for drums of all makes and models including; Rex, Erie, Coneco, Johnson, Ross, Inventure, BMH, etc. We specialize in making the longest-lasting blades available today because we are able to take feedback from producers directly to the factory. We utilize the highest quality materials and combine them with more than 60 years of manufacturing experience to make happy customers from coast to coast.

In the mid-2000’s we were an integral part of getting a new innovation to market: wrap around urethane tips replaced flat urethane liners almost completely. Currently, we are seeing a proven material replace wrap around urethane. Chromium Carbide Overlay has been around for a long time as a wear material but only recently has it been utilized as a central mix blade liner. See this brochure to learn more: Chromium Carbide Overlay (PDF).

-

Request a Quote